| Home | About company | Pumps | Membrane separation | Aerators | Water desinfection |

Planning |

|

EO |

From (m3/d) |

No. of inspec- |

Length (mm) 1st insp. |

Length (mm) 2nd insp. |

Length (mm) 3rd insp. |

For orientation Max. input power (capacity) |

Installed capacity |

100 |

12 |

1 |

2400 |

|

|

5 |

6,4 |

150 |

18 |

1 |

3600 |

|

|

5 |

6,4 |

200 |

24 |

1 |

5700 |

|

|

5 |

6,4 |

250 |

30 |

1 |

7275 |

|

|

6 |

7,2 |

300 |

36 |

1 |

8650 |

|

|

6 |

7,2 |

350 |

42 |

2 |

5400 |

5025 |

|

6 |

7,2 |

400 |

48 |

2 |

5700 |

5700 |

|

6 |

7,2 |

500 |

60 |

2 |

7400 |

7050 |

|

7 |

8 |

600 |

72 |

2 |

8400 |

8900 |

|

7 |

8 |

700 |

84 |

3 |

5700 |

5700 |

8650 |

8 |

9 |

800 |

96 |

3 |

7275 |

7275 |

8650 |

9 |

10 |

1000 |

120 |

3 |

8650 |

8650 |

11400 |

9 |

10 |

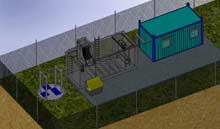

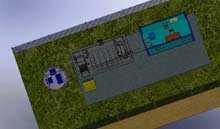

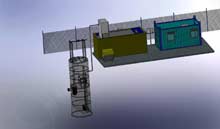

The residential container where the blower, distributor and suction pump with accumulation tank are situated can be replaced with brick object or wooden construction.

The power consumption is the same as in case of common conventional activating waste-water treatment plants with fine-bubble aeration.

An installed capacity is including 2 pcs of pumps in the pumping station.

- Membrane separation

- Catalogue sheets

- Waste-water treatment plant

for 10 000 equivalent residents - Waste-water treatment plant

for 40 000 equivalent residents - References

- Examples of realized

waste-water treatment plants

in the foreign countries

- Project examples of

membrane waste-water

treatment plants

- Container MBR

waste-water treatment

plant of ALVEST type